|

|

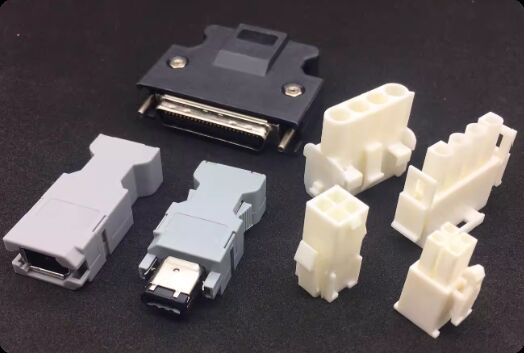

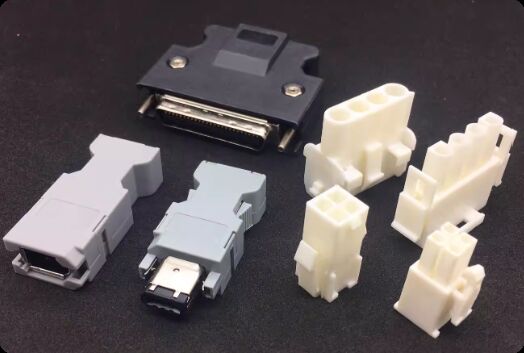

Yaskawa V Series Compatible Servo Motor Connector with Silver and Gold Plated Pins for Industrial Automation

|

Szczegóły Produktu:

Zapłata:

|

| Typ zakończenia: | Zaciskanie/lutowanie | Płeć: | Moog |

|---|---|---|---|

| Aplikacja: | automatyka przemysłowa | Temperatura pracy: | -40 ℃ do +105 ℃ |

| Typ mocowania: | Mocowanie panelu/mocowanie kabla | Liczba kontaktów: | OMRONS DOMOWY |

| Wskaźnik drutu: | Średnica 18-24 AWG lub większa AWG 3-12 | Poszycie kontaktowe: | Srebrna szpilka złota |

| Podkreślić: | Yaskawa V series servo motor encoder plug,servo motor driver connector,servo motor power line quick connector |

||

Applicable Yaskawa V series servo motor encoder plug, driver connector, power line quick connector

![]()

![]()

![]()

![]()

![]()

Product Description:

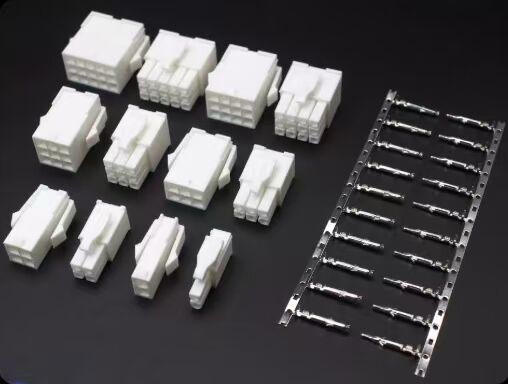

The Servo Motor Connectors are precision-engineered components designed to provide reliable and efficient connections for various types of servo motors, including DC Servo Motor Drive systems, AC Brushless Servo Motor units, and general Brushless Servo Motor applications. Crafted from high-quality metal and plastic materials, these connectors combine durability with flexibility, ensuring long-lasting performance even under demanding operational conditions.

One of the standout features of these Servo Motor Connectors is their superior contact plating. The connectors employ a combination of silver and gold-plated pins, which significantly enhances conductivity and reduces electrical resistance. Silver plating ensures excellent corrosion resistance and optimal electrical performance, while the gold plating on the pins guarantees a stable, low-contact resistance interface. This dual plating approach is especially beneficial in servo motor applications where consistent signal transmission and power delivery are critical.

The connectors are designed to accommodate a range of contact numbers, tailored to meet the needs of various servo motor setups. Specifically, they support configurations compatible with Omrons Domestic servo systems, which are well-regarded for their precision and reliability. This compatibility makes these connectors a preferred choice for integrating with Omrons’ advanced servo motor controllers and drives, facilitating seamless communication and control in automated machinery and robotics.

Current rating is another essential attribute of these Servo Motor Connectors, ensuring they can handle the electrical load required by battery-powered servo systems. The connectors are engineered to safely manage the current demands of servo motors driven by battery sources, which is crucial for maintaining stable operation and preventing overheating or electrical faults. This makes them ideal for use in portable and mobile applications where battery power is the primary energy source.

Wire gauge compatibility is also thoughtfully addressed, with the connectors supporting wire sizes ranging from 18 to 24 AWG or larger. This range allows for flexibility in wiring configurations, accommodating different power and signal transmission needs. Additionally, the connectors can handle wires with diameters from AWG 3 to 12, making them versatile for various industrial and commercial servo motor installations. This adaptability ensures that these connectors can be used across a wide spectrum of servo motor types and sizes, from small precision devices to larger, more powerful systems.

In applications involving DC Servo Motor Drive systems, these connectors ensure efficient power delivery and signal integrity, which are vital for precise motor control and responsiveness. Similarly, in AC Brushless Servo Motor setups, the connectors facilitate stable connections that support smooth motor operation and high performance. Their robust construction and reliable contact plating make them well-suited for the rigorous demands of brushless servo motor technology, where electrical noise and interference must be minimized to achieve optimal control.

Overall, the Servo Motor Connectors are an essential component for anyone working with DC Servo Motor Drive units, AC Brushless Servo Motor systems, or Brushless Servo Motor configurations. Their combination of high-quality materials, advanced plating technology, comprehensive contact options, and broad wire gauge compatibility ensures they meet the highest standards of performance and reliability. Whether used in industrial automation, robotics, or other servo motor-driven applications, these connectors provide the dependable connections necessary for efficient and precise motor control.

Features:

- Product Name: Servo Motor Connectors

- Material: Metal/Plastic for durability and reliability

- Mounting Type: Available in Panel Mount and Cable Mount options

- Voltage Rating: Up to 1000V for high power applications

- Current Rating: Suitable for Battery-powered systems

- Gender: Moog compatible connectors

- Designed for Electro Hydraulic Servo systems

- Compatible with High Torque DC Servo Motors

- Ideal for use with Hydraulic Brake Motors

Technical Parameters:

| Name | Moog ITT Connector |

| Contact Plating | Silver Pin, Golded Pin |

| Termination Type | Crimp/Solder |

| Gender | Moog |

| Operating Temperature | -40℃ To +105℃ |

| Wire Gauge | 18-24 AWG Or More, AWG 3-12 Diameter |

| Application | Industrial Automation (AC Servo Drive, DC Servo Motor Drive, AC Brushless Servo Motor) |

| Connector Type | Servo Motor |

| Voltage Rating | 1000V |

| Mounting Type | Panel Mount/Cable Mount |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a high-quality product originating from China, designed to meet the rigorous demands of various industrial applications. Certified by CE and ISO9001, this connector is built with durable metal and plastic materials, ensuring reliable performance in harsh environments with an operating temperature range from -40℃ to +105℃. With a current rating suitable for battery-powered systems, the connector features silver and gold-plated pins for excellent conductivity and corrosion resistance, making it an ideal choice for precision servo motor connections.

This product is extensively used in scenarios involving DC servo motor drive systems, where precise control and reliable connectivity are crucial for optimal performance. The servo motor connector supports seamless integration with AC servo motor drivers, providing stable and efficient power transmission in automation and robotics applications. Its robust design and high supply ability of 1000 pcs/day make it suitable for large-scale manufacturing and industrial automation projects, where consistent quality and fast delivery are essential.

In electro hydraulic servo systems, the NO MARK servo motor connector plays a vital role in ensuring accurate signal transmission and power delivery. These systems demand connectors that can withstand varying temperatures and mechanical stresses, and this product's metal/plastic construction combined with high-quality contact plating meets these requirements effectively. The connector's compact design and reliable locking mechanism make it easy to install and maintain, reducing downtime in critical applications.

Packaging is done carefully in carton boxes to protect the connectors during transit, with a delivery time of just 1-3 working days, supporting efficient supply chain management. The minimum order quantity is 100 pieces, making it accessible for both small and large orders. Payment terms are flexible, including T/T and PayPal, facilitating smooth and secure transactions for customers worldwide.

Overall, the NO MARK servo motor connector is a versatile and dependable solution for a wide range of servo motor applications, including DC servo motor drives, AC servo motor drivers, and electro hydraulic servo systems. Its combination of high-quality materials, excellent electrical properties, and certifications ensures that it meets the demanding needs of modern industrial and automation environments.

Customization:

Our servo motor connectors, branded as NO MARK and model number servo motor connector, are designed to meet the highest standards of quality and reliability. Originating from China and certified with CE and ISO9001, these connectors ensure excellent performance for various applications including AC Servo Motor Driver, AC Brushless Servo Motor, and Brushless Servo Motor systems.

We offer product customization services with a minimum order quantity of 100 units, packaged securely in carton boxes to maintain product integrity during shipping. With a supply ability of 1000 pcs/day and a delivery time of only 1-3 working days, we guarantee prompt fulfillment of your orders.

The connectors feature a 10PIN insulation resistance and a current rating suitable for battery applications, operating efficiently within a temperature range of -40℃ to +105℃. Specifically designed as servo motor connectors, they are compatible with Moog gender specifications to ensure seamless integration.

Flexible payment terms including T/T and PayPal are accepted to facilitate smooth transactions. Trust our product customization services to deliver high-quality connectors tailored for your AC Servo Motor Driver, AC Brushless Servo Motor, and Brushless Servo Motor needs.

Support and Services:

Our Servo Motor Connectors are designed to provide reliable and secure connections for your servo motor systems. We offer comprehensive technical support to ensure optimal performance and ease of integration.

Technical support includes assistance with product selection, installation guidance, troubleshooting, and maintenance recommendations. Our team of experts is equipped to help you address any challenges and maximize the efficiency of your servo motor applications.

We also provide detailed product documentation, including datasheets, wiring diagrams, and compatibility information to facilitate seamless setup and operation. For custom requirements, we offer tailored connector solutions to meet specific application needs.

Our services extend to product training and on-site support to help your team develop the necessary skills for effective use and upkeep of the servo motor connectors. We are committed to delivering prompt and professional support throughout the product lifecycle.

Osoba kontaktowa: Zhou

Tel: +8613316962478

-

Złącza serwomotorowe ASD-MDBT0100

-

M23 M40 E P Typ połączeń kablowych serwomotorowych 17 pin 12 pin

-

SM-6E 6E SM Servo złącza komplet IEEE1394 6 głównych części kobiecych

-

Serwo SM-6P MOLEX SM6P 1394 6PIN męskie złącze żeńskie

-

J17S-06FMH-7KL-1M-CF PA66 Złącza serwomotorów ze sprężyną Stell

-

Delta B3 Inovance Servo Motor Connector with HDB26 Terminal Board and 3-row 26-pin Wiring for Industrial Automation